Frequantly asked questions about sealants

Here you will find frequently asked questions about joint compound...

Which sealant should I use in a bathroom?

You can use both silicone or a hybrid sealant. Using the product finder on the home page, you can filter the various products that we offer for various applications in the field of sanitation.

Why should you use a skirting board?

When laying a joint in a wall and/or between doors/windows or in a facade, a bottom strip must be installed so that the joint compound can maintain its adhesion to the substrate and achieve its maximum elasticity. Correctly dimensioned joint minimizes the risk of joint loosening or joint failure.

Why should you use a primer?

Primer should be used to strengthen the substrate and for joint compounds to have maximum adhesion to the substrate. This means that the technical performance of the joint compound can be used to the utmost. There are primers for porous and non-porous substrates as well as for different types of joint compounds such as Hybrids or silicone. Which primer is suitable can be read about in the respective joint compound's technical data sheet.

What are the differences between sealant types: hybrid, acrylic and silicone?

Hybrids

Application areas:

- Interior and exterior

- Window installation

- Facade joints

- Movement and floor joints

Characteristics:

High UV resistance and weather resistance, as well as long-lasting elasticity and flexibility.

Application:

Very easy application with suitable tools, at high and low temperatures.

Special feature:

Does not contain solvents and isocyanates. Hybrids allow use on wet substrates and can be overpainted.

Acrylic sealants:

Application areas:

- Mainly interior

- Connection joints with low load

- Interior and drywall

- Crack filling

Characteristics:

UV and weather resistant, non-elastic.

Application:

Very easy application with suitable tool.

Special feature:

Can be painted and plastered over and is paint-compatible.

Silicones:

Application areas:

- Interior and exterior

- Glass construction

- Sanitary area

- Food contact

Characteristics:

Insensitive to UV, weather and high temperatures, highly flexible and elastic in the long term.

Application:

Easy processing with suitable tools, at high and low temperatures.

Special feature:

Extreme UV stability, high temperature resistance and high resilience.

Application instructions - Dimensioning of joints

According to the norm DIN 18540, the minimum joint width should be 10 mm for expansion or connection joints in exterior areas, and the maximum joint width should not exceed 35 mm.

In building construction, the sealant depth should contribute half the sealant width, but should not be less than 8 mm.

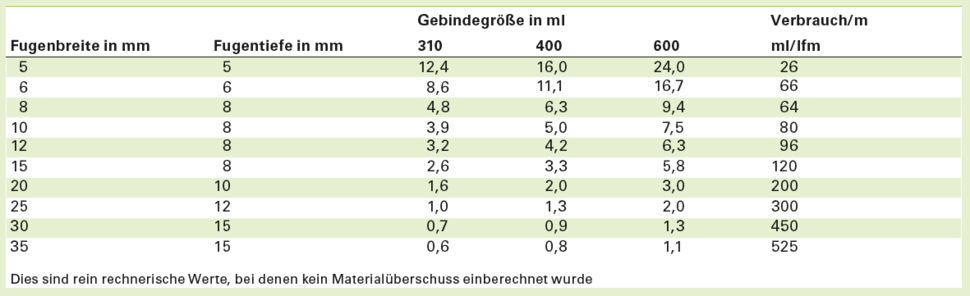

Application instructions - Consumption table for sealants

Application instructions - Backfilling material according to DIN 18540

The use of a closed-cell round cord is necessary to achieve a suitable joint geometry and to prevent three-sided adhesion. The closed-cell illbruck PR012 PE round cord according to DIN 18540 serves as a water-repellent backfill for joints designed for permanent function.

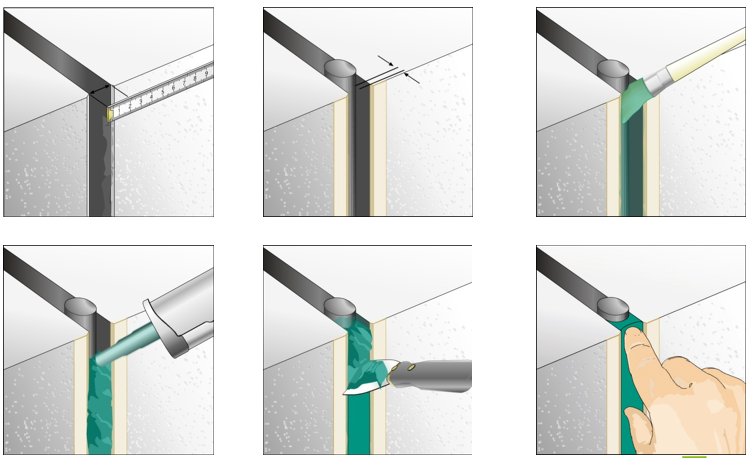

Steps of application

What are the causes for mold growth on sealants?

Most of the causes include:

- A humidity that is higher than 80%

- A temperature of 20° - 35°C

- Suitable breeding ground (dust and smallest dirt particles)

- Little air movement (promotes the sinking of fungal spores)

- Processing errors (e.g. unfavorable joint formation, wrong sealant, wrong smoothing agent)

What are the consequences of mold growth and how can it be prevented?

Consequences of mold growth

- Health risk

- Negative health effects due to mold

- Loss of value

- Costly joint remediation

Avoidance of mold growth

- Ensure sufficient ventilation

- Clean grout surfaces regularly

- Thoroughly rinse & wipe dry after showering/bathing

Note: Even if today's sanitary sealants contain fungicidal, i.e. fungicidal additives, one must not assume a permanent effect, as such protective agents are washed out of the sealant over time.

TIPS for permanent prevention:

- Optimum air humidity in living spaces: 45 to 50%

- Avoid permanently high air humidity, ventilate and heat sufficiently

- Exterior walls should not be colder than 16°C